Southminster Maltings

|

Ale

was considered a very important part of life in the

country until Temperance movement in the later part of

Queen Victoria's Reign. Every village has

several public houses and ale houses and most men brewed

their own ale at home. To cope with the

large volume of brewing small malt houses were common

but there was was a demand for large Maltings. Eastern Essex

produced large amounts of Barley and has an existing

network of Quays allowing Thames barges of taking the

Malt to the main markets in London. This made it a

natural siting of a Malting and about 1845 a Malting

plant was built at Hall Lane, Southminster. THE

PROCESS Barley was stored

in hoppers awaiting process The barley was

sifted remove unwanted husks or other items The Barley was

placed in a large vessel and soaked with water to allow

the grain to swell The grain was

monitored to ensure that it is moist without being

waterlogged The grain was then

drained and allowed to rest before being transferred to

the malting floor The barley was

left untouched to start germination for about a week The barley was

left until it started to sprout The Maltster then

judged when to transfer the barley into the Kiln This judgment was

critical requiring great skill from the Maltster The grain was then

dried and cured to produce malt The length of time

and the heat applied to the kiln determined the type of

malt

SOUTHMINSTER MALTINGS

Southminster Maltings produced large amounts of malt

from about 1845 until it was demolished 1972 to make way

for an industrial estate The Malthouse at

Burnham appears to have closed at about the same time as

by 1871 the census records the address as a disused

Maltings Yard. Likewise the

Southminster malt house that had been run by the

Stebbings family. Water was

important for the process and so several wells were sunk

to tap into underground water. As a benefit to

the community a public pump was installed in hall Road

near to the Maltings to help deal with local water

shortages during dry times The Maltings made

use of the new technique for cast iron in its

construction using iron columns on the ground and first

floor construction although the builders reverted to

wooden columns for the second floor The large volume

of malt is indicated by the provision of five kilns one

of which was conical and the

remainder followed the latest industrial model of being pyramid shaped.

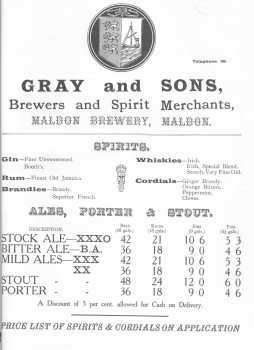

The malt was loaded onto large

carts drawn by horses and taken to Maldon, Chelmsford

and to the local quays

THE MALTSTERS Maltings reflected

two unusual patterns of employment for their era. Firstly Maltsers

often moved large distances between maltings reflecting

the need to ensure skilled men in the key position at

each malting. Secondly there

were not labour intensive as was most occupations,

requiring only a few men to work a large building and

high volume of malt. A snapshot taken from 1871 explains a little about the lives of the many men who worked at the Maltings. In 1871 there were 7 men employed at the Maltings who lived in

cottages on the site.

The Census lists them as

Only George Beale was born in the area wityh the remainder travelling to Maltings that needed their specialist skills.

Samuel Lambard lived with his wife Lucy aged 60 William Lambert

and George Beale were listed as lodgers with Emma Jordan

39 years who is described as widow of Maltster

James Kerridge appears to have

been the expert brought in to run the new Maltings

Census returns for James Kerridge demonstrates life in

the latter part of the 1800's In the 1851 Census

he is listed as a Maltster at Larling, Norfolk In the 1861 Census

he is listed as a Maltster at Coltishall Suffolk In the 1871 Census

he is listed as a Maltster at Southminster Essex In the 1881 Census

he is listed as a Maltster at Southminster Essex In the 1891 Census

he is listed as Parish Clerk/Gardener at Southminster -

He is still at Hall Road but his wife Ann is not listed

although his 18 year old Grand daughter is listed . She

is probably his housekeeper following the death of his

wife Ann

In the 1901 Census he is

listed as Church Clerk/ Gardener. His Grand daughter is

no longer listed but he has a new wife called Susannah

aged 65 |

||||||||||||||||||||||||||||||||